Company guide >> Introduction

Introduction

The Company guide provides methodological guidance in the form of six phases to identify chemicals management hotspots and business opportunities, and implement innovative solutions aimed at improving the sound management of chemicals at companies in the chemical products’ value chain. It helps:

- Choosing the right company and setting up a project team

- Identifying chemicals management hotspots and unmet business needs in the value chain

- Generating innovative options targeting the unmet needs and hotspots

- Evaluating, selecting, implementing and monitoring innovative options

- Reviewing performance and setting up a programme for continuous improvement

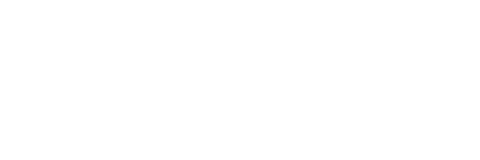

The guide takes a life cycle approach to the Sound Management of Chemicals (SMOC) and chemical waste. It aims at actively improving the sustainability performance of the business’s chemical products along the life cycle.

The methodological approach considers the following life-cycle stages when designing chemical products and services, operations and business models:

- Resource extraction and processing

- Synthesis, formulation and industrial use of chemicals

- Transportation, distribution

- and retail

- Use by industry and consumers

- End of life

Learn more about the methodological approach and its important elements:

Part 1

Part 2

Part 3

Part 1

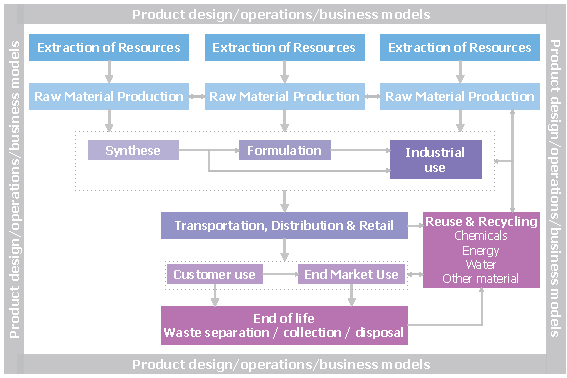

This methodological approach applied to the companies involved in synthesis, formulation or industrial usage of chemicals is composed of following steps:

- Map the company’s chemical products’ value chain

- Identify & characterize chemicals management hotspots having impacts in the following sustainability areas: a) resource use & availability, b) pollution & ecosystem impacts, c) health & safety, d) economic.

- Identify & characterize the “jobs to be done” in the value chain which create value as well as the most important business pains and gains in the value chain. The ones not being currently met or properly serviced are defined as ‘unmet needs’

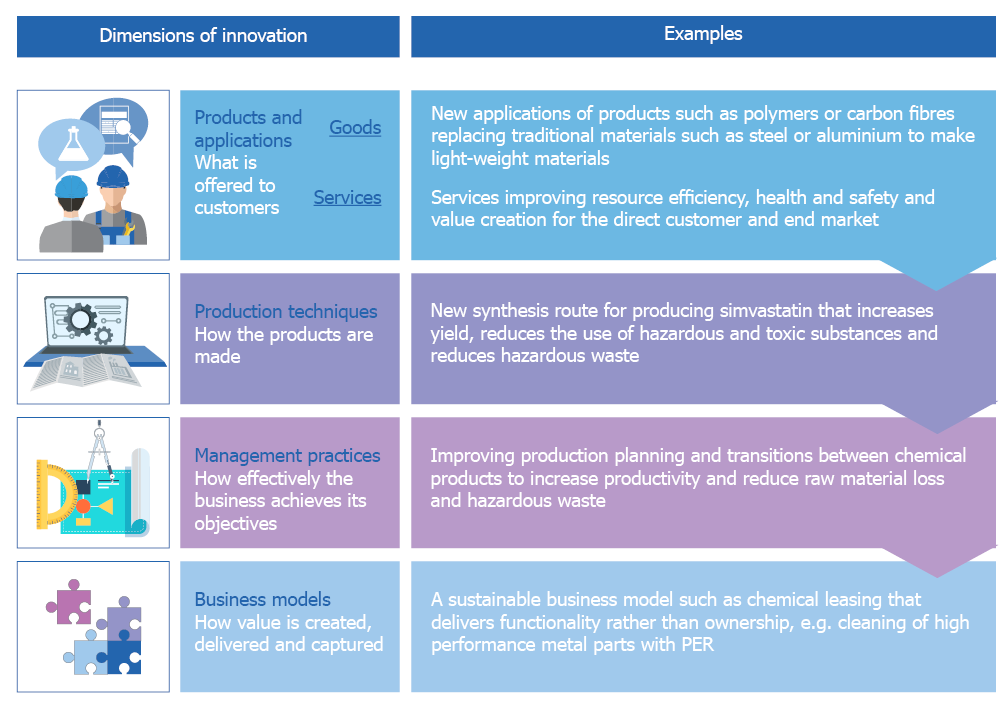

- Use the value chain unmet needs to generate innovations that will improve the chemicals management hotspots and at the same time create value for the company. Innovations can be categorized as: products, production techniques, management practices, and business models.

The methodological approach uses a criteria to identify and define chemicals used in the value chain as Chemicals of High Concern (CoHC) and Chemicals of Concern (CoC). CoHC are considered important chemicals management hotspots to be addressed.

Note: more details on determining if a chemical is a CoHC or a CoC is provided in Phase 2 of the Company guide.

Part 2

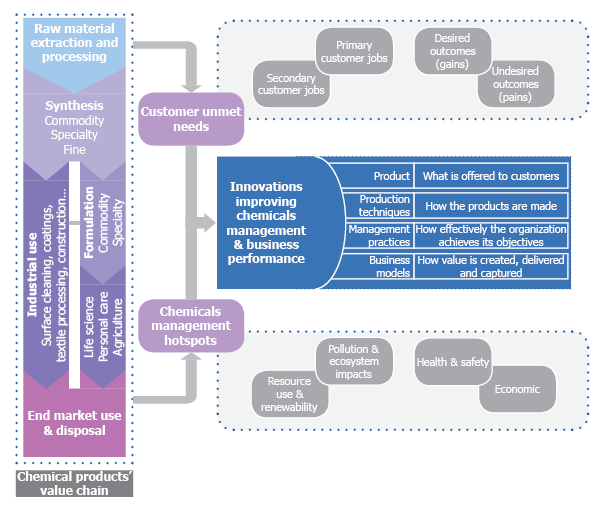

The process for generating innovative options involves the following steps:

- Define challenges & opportunities in the value chain based on chemicals management hotspots and unmet needs.

- Search for potential solutions via three routes: a) Technical resources (TRP 1, TRP 2, TRP3 and sector guidelines), b) analysing market, legal and technology trends, and c) looking at general solutions from other sectors & industries that solve a similar challenge.

- Generate innovative options by integrating potential solutions into the following categories: a) products (goods & services) , b) production techniques, c) management practices, d) business models. Learn 4 dimensions of innovative solutions in the Part 3.

- Capture the main characteristics of the innovative option so it can be properly compared and evaluated with alternative options.

Part 3

The guide provides a flexible framework for generating and applying innovative solutions across the chemical products’ value chain.

1 dimension: Products and applications

Innovations in products and applications (what is offered to customers) can be categorized as:

- Input material change: substitution of ingredients with non-toxic chemicals, renewable feedstocks, secondary (recycled) raw materials and materials with a longer service life-time

- Product modification: modification of product characteristics to minimize impacts to the environment and human health over its life cycle

- Upgrading of by-products: transformation of waste or low-value by-products into materials that can be sold on the market

- New applications: e.g. using materials for new applications such as replacing steel by polymers or carbon composites

- Services: services improving e.g. resource efficiency, health and safety, cost efficiency and value creation for the direct customer and the end market

2 dimension: Production techniques

Innovations in production techniques (how the goods and services are made) can be categorized as:

- On-site recycling or recovery: recover and reuse waste material (e.g. solvent)

- Process change: replace or modify process (e.g. new synthesis route) or processing sequence to improve resource productivity, decrease risk and pollution intensity

- Equipment modification: replace or modify chemical processing or infrastructure equipment to achieve higher resource productivity and reduce pollution and risk

- Optimization of process control and process conditions: control existing processes to optimize their performance and minimize adverse environmental, health and economic impacts

3 dimension: Management practices

- Innovation in management practices (how effectively the organization achieves its objectives) can be categorized as:

- Occupational health and safety management system (e.g. risk assessment, chemical storage rules, workplace rules, emergency response plan)

- Overall improvement programmes like ISO 9000 (quality management)

- Functional improvement programmes such as reliability and maintenance, value stream mapping, standard work, chemical transitions and production planning

4 dimension: Business models

Innovations in business models* (how value is created, delivered and captured) can be categorized as :

- Technological: maximize resource efficiency, create value from waste and substitute with renewable and natural processes

- Social: deliver functionality rather than ownership, adopt a stewardship role and encourage sufficiency

- Organization: repurpose for society/environment: develop scale-up solutions

Tip: Learn about an innovative business model Chemical Leasing